Mechanical seal Huhnseal

ES

balanced single cartridge seal

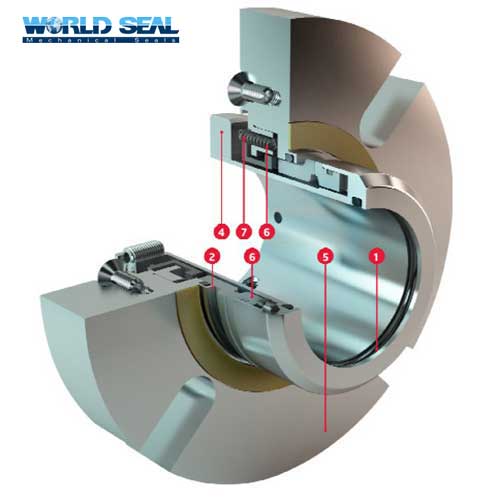

Huhnseal ES is a balanced single mechanical seal with a unique and modern design. The springs are not placed directly behind the stationary face, this being the most common competitor solution, but have been located on a larger diameter further away from the critical O-ring and seal face gap in order to reduce risk for clogging. Due to the relocation of the springs, more robust springs may be used enabling to change from compression to tension springs. The robust tension spring design gives the seal better performance since it is more difficult for particles and fibers from the product to reach and clog up the springs. Additionally, the relatively long springs with larger wire diameter increase the axial and radial movement capabilities of the seal.

First-class materials from carefully selected suppliers ensure optimized performance at minimized built-in dimensions.

Features Mechanical seal ES:

- Cartridge mounted for easy assembly

- Balanced (ES) and double balanced (ED) design for minimum heat generation

- Both ES and ED have excellent axial and radial movement capabilities

- Suitable for standardization

- Robust construction materials as standard:

- Acid resistant stainless steel

- Graphite loaded sintered silicon carbide

- Peroxide cured FPM for ES

- FFPM for ED

- Easy and time efficient to recondition on site when required

- Protected spring package to minimize risk for clogging

- The seals may be equipped with a separarate flange for flushing

Application mechanical seal es

- Clean fluids*

Material starndard mechanical seal es

- Rotating face product side: SSiC+C

- Stationary face product side: SSiC

- Rotating face atmospheric side: TC

- Stationary face atmospheric side: Carbon

- Elastomer: EPDM / FPM / FFPM

- Springs: HASTELLOY CTM, EN 1.4401

- Metal parts: EN 1.4404

Material on request mechanical seal es

- Rotating face product side: TC

- Stationary face product side: TC

- Rotating face atmospheric side: –

- Stationary face atmospheric side: SSiC

- Elastomer: EPDM / FPM / FFPM

- Springs: HASTELLOY CTM, EN 1.4401

- Metal parts: Titanium

Features mechanical seal es

Huhnseal ES is a balanced single mechanical seal with a unique and modern design. The springs are not placed directly behind the stationary face, this being the most common competitor solution, but have been located on a larger diameter further away fom the critical O-ring and seal face gap in order to reduce risk for clogging. Due to the relocation of the springs, more robust springs may be used enabling to change from compression to tension springs. The robust tension spring design gives the seal better performance since it is more difficult for particles and fibers from the product to reach and clog up the springs. Additionally the relatively long springs with larger wire diameter increase the axial and radial movement capabilities of the seal.

First-class materials from carefully selected suppliers ensure optimized performance at minimized built-in dimensions.

Operating range mechanical seal es

- Pmax = 25 bar

- Tmax = 100°C

- Vmax = 18 m/s (3600 rpm)

- Axial movement: ±2,0 mm

- Hygienic solutions mechanical seal es

Smooth surfaces without cavities or closed spaces make the seal suitable for food and drug application. If required the gasket may be replaced with O-rings in execution according to EHEDG to achieve a hygienic designed seal suitable for CIP (Cleaning in Place). - Excellent angular movement capabilities seal es Advantage when operating against closed valves, causing shaft bending.

- H4 design mechanical seal es

The rotating sealing face on the product side has the new “H4-design”. This means that the seal is O- ring mounted and the outer diameter of the seal face is the same as of the holder. This prevents the forming of turbulent flows, which cause heavy wear in abrasive liquids. - Advantageous built-in dimensions seal es

Fits in most standard pump stuffing boxes. - Optional additional flange for flushing seal es

The seal may be equipped with an extra flange when flushing into the media is needed. The standard design is without flange since the chamber with a small gap given by the flushing flange may encourage material build-up if flush is not connected. - Spring package located on the outside of the flange seal es

This design is better protected against fiber and particle build-up, which eventually causes clogged- up springs. - Patented tension springs mechanical seal es

Allow for an excellent axial movement of ± 2,0 mm.

Patent No: 9803436-6