Mechanical seal Huhnseal

ED

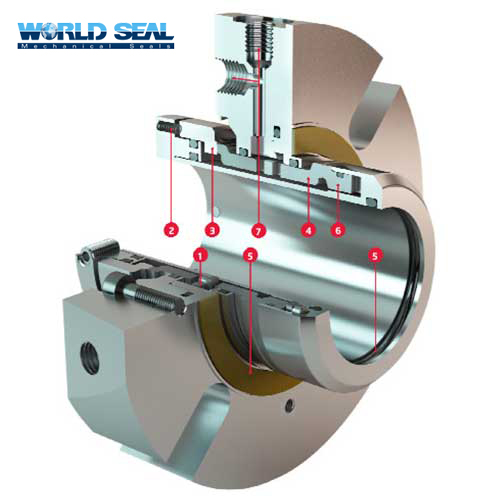

Balanced double cartridge seal

Huhnseal ED is a double balanced cartridge seal maintaining sealing performance even during sudden pressure drops on the product side and/or the secondary side. The design of the seal is robust and rigid but at the same time flexible, with excellent radial and axial movement capabilities. The springs are located outside both the product and the flush minimizing risk for clogging.

Features Mechanical seal ED:

- Cartridge mounted for easy assembly

- Balanced (ES) and double balanced (ED) design for minimum heat generation

- Both ES and ED have excellent axial and radial movement capabilities

- Suitable for standardization

- Robust construction materials as standard:

- Acid resistant stainless steel

- Graphite loaded sintered silicon carbide

- Peroxide cured FPM for ES

- FFPM for ED

- Easy and time efficient to recondition on site when required

- Protected spring package to minimize risk for clogging

- The seals may be equipped with a separarate flange for flushing

Application mechanical seal ed

- Fluids with poor lubrication capabilities

- Crystallizing fluids

- Fluids reacting with air

- Sedimentary fluids

- High temperature fluids ( >100°C )

- Fluids hazardous to health and enviroment

- Extra need of cooling / pressure balancing

Material starndard mechanical seal ed

- Rotating face product side: SSiC+C

- Stationary face product side: SSiC

- Rotating face atmospheric side: TC

- Stationary face atmospheric side: Carbon

- Elastomer: EPDM / FPM / FFPM

- Springs: HASTELLOY CTM, EN 1.4401

- Metal parts: EN 1.4404

Material on request mechanical seal ed

- Rotating face product side: TC

- Stationary face product side: TC

- Rotating face atmospheric side: –

- Stationary face atmospheric side: SSiC

- Elastomer: EPDM / FPM / FFPM

- Springs: HASTELLOY CTM, EN 1.4401

- Metal parts: Titanium

Features mechanical seal ed

Huhnseal ED is a double balanced cartridge seal maintaining sealing performance even during sudden pressure drops on the product side and/or the secondary side. The design of the seal is robust and rigid but at the same time flexible, with excellent radial and axial movement capabilities.

The springs are located outside both the product and the flush minimizing risk for clogging.

Operating range mechanical seal ed

- Pmax = 25 bar

- Tmax = 100°C

- Vmax = 18 m/s (3600 rpm)

- Axial movement: ±2,0 mm

- Excellent axial movement mechanical seal ed

The seal can move ± 2,0 mm independent of the compression of the springs. The seal follows the movement of the shaft without influencing the compression of the springs. This feature is essential when sealing equipment with flexible bearing units. - Patented protected spring package seal ed

The springs are located outside both the product and the flush. Minimizing the risk for clogging, which is one of the most common causes for seal failure. Patent No: 900912-2 - Safe drive of rotating surface at the atmospheric side

The rotating face on the atmospheric side is driven by three big drive pins machined into the sealing face. The pins are not in contact with the quench liquid, eliminating the risk of them being blocked axially by residues from the quench. - Excellent radial movement capabilities seal ed

Through a new design the seal is able to compensate for angular deviation without generating stresses over the seal faces, which may influence sealing performance. This feature minimizes the effects of excessive shaft bending during operation against closed valves. - Hygienic applications mechanical seal ed

Smooth surfaces without cavities or closed spaces make the seal suitable for food and drug applications. If required, the gasket may be replaced with O-rings according to EHEDG in order to achieve a hygienic designed seal suitable for CIP (Cleaning in Place). - H4 design mechanical seal ed

The rotating sealing face on the product side has the new “H4-design”. This means that the seal face is O-ring mounted and the outer diameter of the seal face is the same as of the holder. This prevents the forming of turbulent flows, which cause heavy wear in abrasive liquids. - Axial cooling channels

Allow for installation of a double seal in applications with very limited space.