Mechanical seal H-brinker

HBSR

Operating range Mechanical seal HBSR

Shaft diameter: 24.5 … 320.3 mm (0.96″ … 12.61″)

Design pressure: p = 0.5 … 10 bar (7.25 … 145 PSI)

Operating pressure: p = 0.5 … 0.8 bar (7.25 … 11.60 PSI)

Temperature: t = -20 °C … +200 °C (-4 °F … +392 °F)

Sliding velocity: vg = 10 …140 m/s (33 … 459 ft/s)

Separation gas dew point at 0.8 bar (11.6 PSI): t = -50 °C … -20 °C (-58 °F … -4°F)

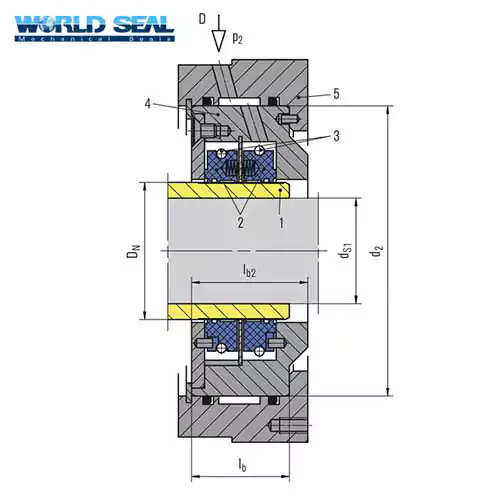

Table of Mechanical seal descriptions HBSR

| Item | Description |

| 1 | Shaft sleeve |

| 2 | Segmented carbon ring |

| 3 | Garter spring |

| 4 | Housing of standardized sub-cartridge |

| 5 | Housing (size matched to installation space) |

| D | Separation gas |

Features Seal HBSR

- Contacting bushing seal

- Gas-lubricated

- Bi-directional

- Ready-to-fit cartridge unit

Advantages mechanical seal HBSR

- Very low leakage

- No increased leakage in static operation

- Small gas consumption

- Optimized carbon material for operation with ultra dry nitrogen

- For continuous operation with little shutdowns and slow roll operation >10m/s

Materials Seal HBSR

- Seal face: Carbon graphite impregnated

- Secondary seals: FKM

- Shaft sleeve: Stainless steel TC-coated

- Metal parts: 1.4006 or other stainless steels.

Recommended applications seal HBSR

- Oil and gas industry

- Refining technology

- Petrochemical industry

- Nitrogen

- Air

- Centrifugal compressors

- Blowers