Mechanical seal H-brinker

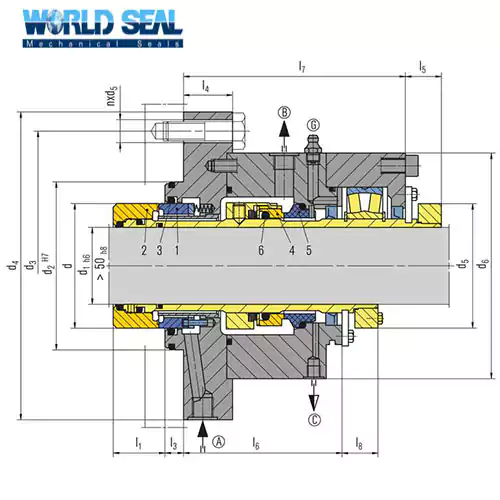

HBSMR34

Operating range Mechanical seal HBSMR34

Shaft diameter: d1 = 35 … 140 (500) mm (1.38” … 5.51” (19.68”))

Axial offset shaft/housing: d1 = 35 … 60 mm (1.38” … 2.36”): max. ±1.5 mm (0.059”) d1 >60 mm (2.36”): max. ±2.0 mm (0.079”)

Radial offset shaft/housing: max. ±0.3 mm (0.012”)

Pressure:

p1 = vacuum … 14 (23) bar (203 (334) PSI)

p3 = max. 16 (25) bar (232 (363) PSI)

Δ p3-p1 = 2 …10 bar (29 …145 PSI),

higher Δp on request

Temperature: t1 = -20 °C … +200 (300) °C (-4 °F … +392 (572) °F)

Sliding velocity: vg = max. 10 (20) m/s (33 (66) ft/s)

Table of Mechanical seal descriptions HBSMR34

| Item | Description |

| 1 | Seal face, product side |

| 2 | Seat, product side |

| 3, 6 | O-Ring, dynamic |

| 4 | Seal face, atmosphere side |

| 5 | Seat, atmosphere side |

Features Seal HBSMR34

- For top, side and bottom entry drives

- Seat at product side rotating

- Unbalanced

- Liquid-lubricated

- Double seal

- Independent of direction of rotation

- Cartridge unit

- With or without bearing available

- Shaft sleeve not in contact with product (with standard diameters)

Advantages mechanical seal HBSMR34

- Smooth surface, free of dead spaces

- CIP-/SIP (Cleaning in Place,

- Sterilization in Place) capable

- Sliding materials FDA conform

- Variant for sterile applications available

- ATEX certification on request

Materials Seal HBSMR34

- Seal faces: Silicon carbide, FDA conform

- Seat: Carbon graphite (atmosphere side) resp. Silicon carbide (product side), FDA conform

- Secondary seals and metallic parts acc. to application and customers’ requirement.

Recommended applications seal HBSMR34

- Petrochemical industry

- Chemical industry

- Pharmaceutical industry

- Food and beverage industry

- Mixers

- Dryers

- Mills

- Kneaders

- Reactors

- Pressure filters