Mechanical seal H-brinker

HBSM481

Operating range Mechanical seal HBSM481

Shaft diameter: d1 = 40 … 220 mm (1.57″ … 8.66″)

Pressure: p1 = vacuum … 6 bar (87 PSI)

Temperature: t1 = -20 °C … +200 (250*) °C (-4 °F … +392 (482*) °F)

Sliding velocity: vg = 0 … 2 m/s (0 … 6 ft/s)For applications beyond this range, please inquire.

* with cooling flange

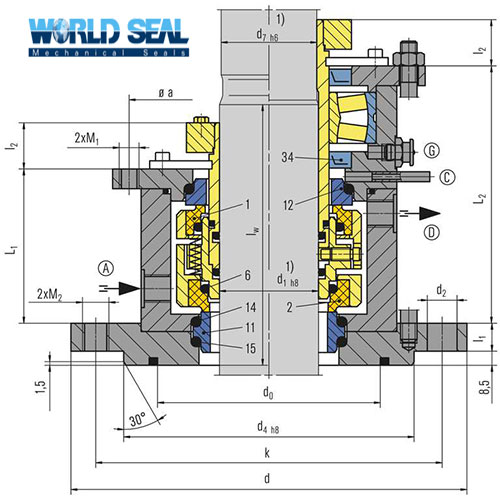

Table of Mechanical seal descriptions HBSM481

| Item | Description |

| 1 | Seal face, atmosphere side |

| 2 | Seal face, product side |

| 6, 14, 15 | O-Ring |

| 11 | Seat, product side |

| 12 | Seat, atmosphere side |

| 34 | Lip seal |

Features Seal HBSM481

- For top entry drives

- For steel vessels acc. to DIN resp. Non-DIN

- Nitrogen pressurized dual seal, single seal optional

- Balanced

- Independent of direction of rotation

- Multiple springs rotating

- Dry running

- Cartridge unit

Advantages mechanical seal HBSM481

- Ready-to-fit and factory-tested unit

- With or without bearing available

- Suitable for pressure reversal e.g. in case of barrier pressure failure

- No contamination of the product by barrier fluid

- Friction-locked connection to the shaft

- Connections to DIN 28138 standards or as required (SeccoMix 451)

- ATEX certification available on request

Materials Seal HBSM481

- Seal face: Carbon graphite, FDA conform

- Seat: Silicon carbide, FDA conform

- Secondary seals and metal parts according to application and customer’s specifications.

Recommended applications seal HBSM481

- Refining technology

- Petrochemical industry

- Chemical industry

- Pharmaceutical industry

- Food and beverage industry

- Agitators

- Mixers

- Reactors

Dimension Table Seal HBSM481

| d11) | d71) | d | n x d2 | d4 | d0 | k | L1 | L2 | Lw2) | l1 | l2 | A | M1 | M1 | A, B |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 38 | 175 | 4×18 | 110 | 90 | 145 | 87 | 136 | 143 | 15 | 28 | 122 | M12 | M16 | G3/8 |

| 50 | 48 | 240 | 8×18 | 176 | 135 | 210 | 89 | 149 | 148 | 17 | 28 | 157 | M12 | M16 | G3/8 |

| 60 | 58 | 240 | 8×18 | 176 | 135 | 210 | 93.5 | 156 | 158 | 17 | 28 | 168 | M12 | M16 | G3/8 |

| 80 | 78 | 275 | 8×22 | 204 | 155 | 240 | 104.5 | 189 | 168 | 20 | 34 | 203 | M16 | M20 | G1/2 |

| 100 | 98 | 305 | 8×22 | 234 | 190 | 270 | 109 | 190 | 178 | 20 | 34 | 228 | M16 | M20 | G1/2 |

| 125 | 120 | 330 | 8×22 | 260 | 215 | 295 | 110 | 205 | 203 | 20 | 40 | 268 | M20 | M20 | G1/2 |

| 140 | 135 | 395 | 12×22 | 313 | 250 | 350 | 124 | 222 | 208 | 20 | 40 | 285 | M20 | M20 | G1/2 |

| 160 | 150 | 395 | 12×22 | 313 | 265 | 350 | 127.5 | 219.5 | 213 | 25 | 40 | 297 | M20 | M20 | G1/2 |

| 180 | 170 | 445 | 12×22 | 364 | 310 | 400 | 132.5 | 230 | 233 | 25 | 45 | 332 | M24 | M20 | G1/2 |

| 200 | 190 | 445 | 12×22 | 364 | 310 | 400 | 137.5 | 237.5 | 243 | 25 | 45 | 352 | M24 | M20 | G1/2 |

| 220 | 210 | 505 | 16×22 | 422 | 340 | 460 | 149.5 | 249.5 | 263 | 25 | 50 | 381 | M24 | M20 | G1/2 |