Mechanical seal H-brinker

HBSLip481

Operating range Mechanical seal HBSLip481

Shaft diameter (on stock): d1 = 40 … 125 mm (1.57″ … 4.92″)

Special shaft diameters between 25 mm and 200 mm possible (0.98″ … 7.87″)

Pressure: p1 = vacuum … 6 bar (87 PSI)

Temperature: -30 °C … +200 °C (-22 °F … +392 °F)

Sliding velocity: vg = 0 … 2 m/s (0 … 6 ft/s)

Axial movement: ±3.0 mm

Radial movement: 1.0 mm (up to 3 mm on request)For applications beyond this range, please inquire.

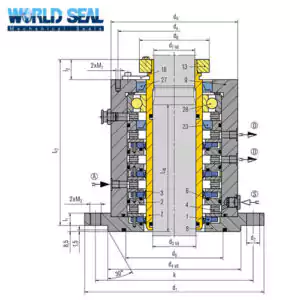

Table of Mechanical seal descriptions HBSLip481

| Item | Description |

| 1 | Lip seal |

| 2 | Inset |

| 3 | Disc |

| 4 | Insert ring |

| 6 | O-Ring |

| 7 | Shaft sleeve |

| 8 | Flange |

| 9 | Housing |

| 13 | Shrink disc |

| 16 | Setting device |

| 23 | Spacer ring |

| 27 | Lip seal |

| 28 | Sliding bearing |

Features Seal HBSLip481

- For top entry drives, on request other drives possible

- Dry-running

- Modular and flexible design

- Compensation of shaft deflection by patented technology

- Independent of direction of rotation

- Cartridge unit

Advantages mechanical seal HBSLip481

- Available as a ready-to-mount cartridge for quick and easy installation

- Tested technology ensures safe use

- Dry-running lip seal – depending on the application no supply system is necessary

- No additional rolling bearing required, but optionally available

- Sealing element made of bright chemically highly resistant PTFE compound

- ATEX certificate on request

- Customized adjustments possible

Materials Seal HBSLip481

- Lip sealing element: bright chemically highly resistant PTFE-compound with FDA

- Secondary seals: FKM (V)

- Metallic parts: 316L / 1.4404

- Other materials are possible, depending on customer requirements.

Recommended applications seal HBSLip481

- Chemical industry

- Petrochemical industry

- Pharmaceutical industry

- Food and beverage industry

- Agitators

- Mixers

- Reactors

Dimension Table Seal HBSLip481

| d3 | d1 | nxd2 | d4 | d0 | k | d8 | d9 | L1 | l1 | l2 | da | M1 | M2 | S |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 175 | 4×18 | 110 | 90 | 145 | 80 | 175 | 91.5 | 19.5 | 26 | 145 | M8 | M16 | G1/4 |

| 50 | 240 | 8×18 | 176 | 135 | 210 | 90 | 168 | 91.5 | 19.5 | 28 | 153 | M8 | M16 | G1/4 |

| 60 | 240 | 8×18 | 176 | 135 | 210 | 100 | 178 | 91.5 | 18 | 27.5 | 155 | M8 | M16 | G1/4 |

| 80 | 275 | 8×22 | 204 | 155 | 240 | 130 | 198 | 100.5 | 21 | 33.5 | 175 | M8 | M20 | G1/4 |

| 100 | 305 | 8×22 | 234 | 190 | 270 | 150 | 218 | 102.5 | 23 | 33.5 | 195 | M8 | M20 | G1/4 |

| 125 | 330 | 8×22 | 260 | 215 | 295 | 179 | 243 | 107.5 | 23 | 38.5 | 220 | M8 | M20 | G1/4 |