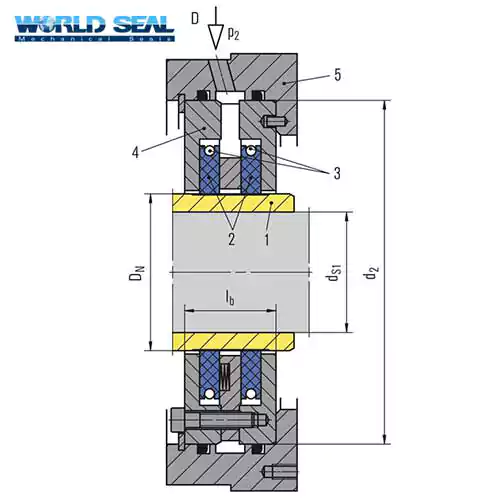

Mechanical seal H-brinker

HBSE

Table of Mechanical seal descriptions HBSE

| Item | Description |

| 1 | Shaft sleeve |

| 2 | Segmented carbon ring |

| 3 | Garter spring |

| 4 | Housing of the standardized sub-cartridge |

| 5 | Housing (size matched to installation space) |

| D | Separation gas |

Features Seal HBSE

- Non-contacting bushing seal

- Gas-lubricated

- Bi-directional

- Ready-to-fit cartridge unit

- Equipped with Espey carbon rings type WKA400

Advantages mechanical seal HBSE

- Low leakage

- Slow roll capability

- Insensitive to dry nitrogen

Materials Seal HBSE

- Seal face: Carbon graphite impregnated

- Secondary seals: FKM

- Shaft sleeve: Stainless steel, TC-coated

- Metal parts: 1.4006 or other stainless steels

Recommended applications seal HBSE

- Oil and gas industry

- Refining technology

- Petrochemical industry

- Nitrogen

- Air

- Centrifugal compressors

- Turbo expanders

- Screw compressors

- Blowers