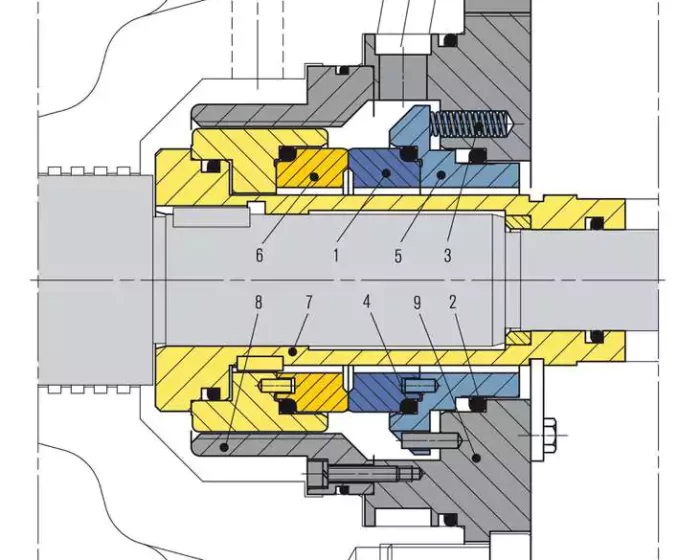

Mechanical seal H-brinker

HBDF-SA

Table of Mechanical seal descriptions HBDF-SA

| Item | Description |

| 1 | Seal ring |

| 2 | O-Ring |

| 3 | Spring |

| 4 | O-Ring |

| 5 | Seat collar |

| 6 | Mating ring (DiamondFace coated) |

| 7 | Shaft sleeve |

| 8 | Pumping sleeve |

| 9 | Cover |

Features Seal HBDF-SA

- Cartridge design

- Single seal

- Balanced

- Integrated pumping device

- Stationary spring loaded unit

- Inserted seal ring

- Rotating mating ring

(DiamondFace coated)

Advantages mechanical seal HBDF-SA

- Resistant to electrochemical corrosion.

- Extremely long service life (>40,000 h).

- No dosing system, no cooling circuit conditioning required.

- Diamond coating provides very low friction, thus reduced power consumption.

- Deformation-optimized for high sliding velocities and medium pressures.

- Economical due to standardized components.

- High flexibility due to adaptation of the connection parts to the pump seal chamber.

- Optimum heat dissipation due to integrated pumping device and optimized seat / seal face design.

Materials Seal HBDF-SA

- Seal face: Composite carbon

- Seat: SiC DiamondFace coated

- Secondary seals: EPDM (E), FFKM (K)

- Springs: CrNiMo steel (G)

- Metal parts: CrNiMo steel (G)

Recommended applications seal HBDF-SA

- Power plant technology

- Boiler feed pumps