Mechanical seal H-brinker

HB4600SH

Operating range Mechanical seal HB4600SH

Shaft diameter: d1 = 50 … 320 mm (1.97″ … 12.60″)

Pressure: p = 2 … 7 bar (29 … 102 PSI)

Temperature: t = -5 °C … 40 °C (23 °F… 104 °F)

Speed range: n = see diagram

Allowed shaft movements

Axial: ±5 mm,

Radial: Shaft diameter (d1) up to 200 mm: ±2 mm, >200 mm: ±3 mm

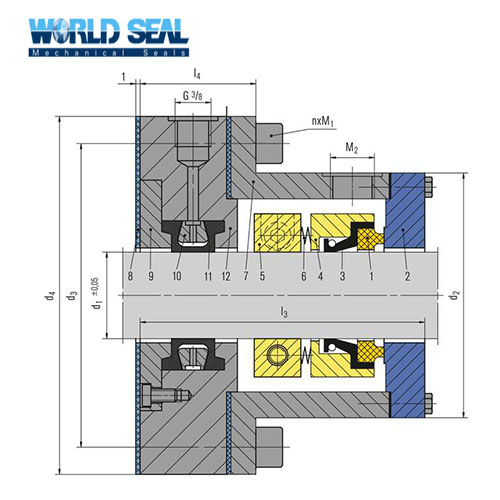

Table of Mechanical seal descriptions HB4600SH

| Item | Description |

| 1 | Seal face |

| 2 | Mating ring |

| 3 | Collar |

| 4 | Face housing |

| 5 | Clamping ring |

| 6 | Springs |

| 7 | Housing |

| 8 | Gasket |

| 9 | Cover |

| 10 | Back-up ring |

| 11 | Shut down seal |

| 12 | Flange |

Features Seal HB4600SH

- The water-lubricated stern tube seals type hb4600 from

- EagleBurgmann are not alone an environment-friendly solution.

- They meet all technical requirements of modern sealing technology: modular design, convenient installation, little maintenance, no adjustments.

- Applying a shut down seal eliminates costly and time-consuming dry-docking.

- Maintenance and repairs can be performed with vessel afloat.

- hb4600 water-lubricated stern tube seals are virtually leak-free and are leaving no oil or grease residues in the waterway. And because they prevent getting water into the bilge, no elaborate actions are required for its disposal.

Advantages mechanical seal HB4600SH

- With shut down seal

- Water-lubricted

- No oil or grease emissions to the environment

- Low power consumption

- Carbon seal face unsplit for first installation, split for repairs

- Version with split mating ring available

Materials Seal HB4600SH

- Seal face: Carbon graphite antimony impregnated (A),

Carbon graphite resin impregnated (B) - Mating ring: Special cast CrNiMo steel (S) / 1.4462

Collar, shut down - seal:

Nitrile-butadiene rubber (P) - Springs: Hastelloy® C-4 (M) /1.4401

- Gasket: Burasil® (Y)

- Metal parts: 1.4571 / Bronze

Recommended applications seal HB4600SH

- Shipbuilding

- Sea water

- Fresh water

Dimension Table Seal HB4600SH

| d1 | d2 | d3 | d4 | l3 | l4 | M1 | M2 | n |

|---|---|---|---|---|---|---|---|---|

| 50 | 125 | 142 | 165 | 150 | 55 | M10 | G1/2″ | 4 |

| 60 | 135 | 152 | 175 | 150 | 55 | M10 | G1/2″ | 4 |

| 70 | 145 | 185 | 215 | 150 | 55 | M16 | G1/2″ | 4 |

| 80 | 155 | 195 | 225 | 155 | 55 | M16 | G1/2″ | 4 |

| 90 | 165 | 205 | 235 | 155 | 55 | M16 | G1/2″ | 4 |

| 100 | 175 | 215 | 245 | 155 | 55 | M16 | G1/2″ | 4 |

| 110 | 192 | 230 | 260 | 160 | 55 | M16 | G1/2″ | 6 |

| 120 | 202 | 240 | 270 | 160 | 55 | M16 | G1/2″ | 6 |

| 130 | 212 | 250 | 280 | 160 | 55 | M16 | G1/2″ | 6 |

| 140 | 222 | 260 | 290 | 160 | 55 | M16 | G1/2″ | 6 |

| 150 | 232 | 270 | 300 | 160 | 55 | M16 | G1/2″ | 6 |

| 160 | 242 | 280 | 310 | 160 | 55 | M16 | G1/2″ | 6 |

| 170 | 252 | 290 | 320 | 160 | 55 | M16 | G1/2″ | 6 |

| 180 | 262 | 300 | 330 | 170 | 55 | M16 | G1/2″ | 6 |

| 190 | 272 | 310 | 340 | 170 | 55 | M16 | G1/2″ | 8 |

| 200 | 282 | 320 | 350 | 170 | 55 | M16 | G1/2″ | 8 |

| 210 | 292 | 330 | 360 | 170 | 55 | M16 | G1/2″ | 8 |

| 220 | 302 | 340 | 370 | 170 | 55 | M16 | G1/2″ | 8 |

| 230 | 312 | 350 | 380 | 170 | 55 | M16 | G1/2″ | 8 |

| 240 | 340 | 365 | 405 | 180 | 60 | M20 | G1/2″ | 8 |

| 250 | 350 | 375 | 415 | 180 | 60 | M20 | G1/2″ | 8 |

| 260 | 360 | 385 | 425 | 180 | 60 | M20 | G3/4″ | 8 |

| 270 | 370 | 395 | 435 | 180 | 60 | M20 | G3/4″ | 8 |

| 280 | 380 | 405 | 445 | 180 | 60 | M20 | G3/4″ | 8 |

| 290 | 390 | 415 | 455 | 180 | 60 | M20 | G3/4″ | 8 |

| 300 | 400 | 425 | 465 | 180 | 60 | M20 | G3/4″ | 8 |

| 310 | 420 | 445 | 485 | 180 | 60 | M20 | G3/4″ | 8 |

| 320 | 430 | 455 | 495 | 180 | 60 | M20 | G3/4″ | 8 |